By Kate Gordon

It’s official: we’re in a time of energy transition. On April 22, Earth Day, the UN’s most recent climate agreement—known as the Paris Agreement—will be formally signed in New York, ushering in a new era of country-led action to reduce carbon emissions. For the first time, individual countries have specific and (politically, if not legally) binding commitments to reduce greenhouse gas emissions, which they will feed into an international process to measure progress every five years.

We should celebrate, for sure. But now we enter the tough phase, where we start to understand just what it will take to make this kind of economic transition. Much attention has been focused on the decline of coal as a primary power source, and the increasing role of renewable energy and energy efficiency in the new energy landscape.

What’s less clear is what will happen to the industrial sector in a new and more sustainable economic model. To some environmentalists, heavy industry, accounting for 21% of direct global greenhouse gas emissions in 2010 and a full third of all emissions once we include emissions from electricity consumed by industry, is antithetical to progress. But these same industries—steel, cement, aluminum, copper, and other raw materials—form the backbone of our modern economic system. They are the foundation of every country’s move from rural to urban societies, bringing increased wages and improved quality of life. You can’t build a city without cement and steel, and countries like China and India are building cities fast. And lest we forget, the renewable energy systems and green buildings at the center of most low-carbon urban development plans are made in large part with these same materials.

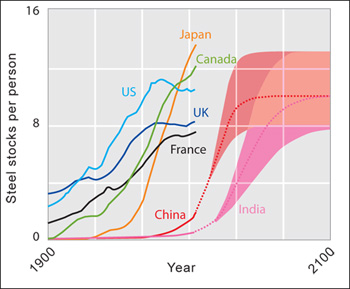

Steel use in particular is a pretty good proxy for urbanization—the more steel per person a country uses, the more urbanized it likely is. Consider this: in the U.S., where 80% of the population lives in urban areas, there were about 14 tons of steel per person in 2008; this number has stayed fairly flat since we are already such an urbanized country. But in China, there were just 3.3 tons of steel per capita that same year, and in India only 0.7 tons. With only half of Chinese and a third of Indians living in urban areas (and China, for its part, expecting 100 million people to move to urban areas in the next 5 years), demand for steel and other essential building materials will only increase in the coming decades in these countries, as well as in other developing nations in Africa and South America.

If we expect developing countries to reach anywhere close to the standards of living enjoyed by wealthy countries while still fulfilling global climate goals, countries must integrate solutions for heavy industry into their climate plans rather than sidelining them as part of the problem. These solutions can take a variety of forms: first, countries should commit to closing down the dirtiest and most inefficient industrial plants. China could lead the way: its commitment to reduce overcapacity in its steel sector should start with action to close down its worst-performing plants, including some state-owned enterprises, and include a well-thought-out worker transition program to soften the blow for the millions who will lose their jobs.

But we can’t close all the steel, iron, and concrete factories in the world and still maintain any sort of modern economy. So those that remain open must become leaner and more efficient—for instance through replacing coal-fired furnaces with electric arc furnaces at steel plants, which also allow those plants to shift to using recycled steel scrap instead of generating new steel. New low-carbon cement can replace traditional cement over time, and every industrial facility can shift from buying dirty power off the grid to producing power from waste heat generated from furnaces and other industrial processes. Even in the industrialized and fairly efficient U.S., the Department of Energy estimates that industrial energy consumption could be reduced by an additional 15 to 32 percent from 2012 levels by 2025 through accelerated adoption of these types of energy efficiency technologies.

Another way for developing countries to grow economically without increasing pollution is to build cities using fewer raw materials and high-polluting processes. New ride-sharing programs, combined with accessible and affordable mass transit, can dramatically reduce the need for cities to build out highway systems. New designs for wind turbines, like Google’s Makani wind business, replace the steel-intensive traditional turbine with a power-generating kite combined with software controls. As these kinds of next-generation technologies take off, developing countries may be able to leapfrog traditional industrial development and achieve high standards of living using far less raw material than was previously possible.

All these solutions require the macro-level commitments made in Paris to come down to the local level, where planning and infrastructure decisions are usually made. They require strong government support for research and development of new technologies, and for financing systems that encourage public and private investments in these low-carbon systems. They require innovation and entrepreneurship on the part of the private sector. But perhaps most important, they require a shift in thinking: from seeing heavy industry as the villain, to seeing low-carbon industrial growth as a key weapon in the fight against climate change.